5 Uses for Augmented Reality in Manufacturing

Augmented Reality, also known as AR, is a newer technology that is becoming more and more prevalent in today’s world. It is integrating with our daily lives at a steady pace, and there is no telling where it could go. Right now, there are apps, like Pokemon GO, and shopping tools, like Amazon’s AR tool for visualizing furniture in your home.

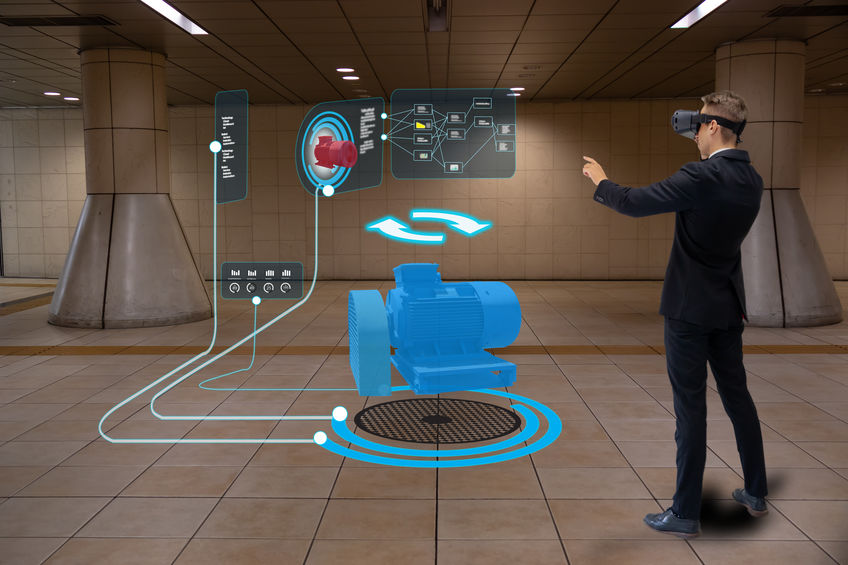

Augmented Reality is a type of technology that integrates the real world and virtual reality. With virtual reality, you put on a headset and are placed into a fully virtual world around you. With virtual reality, it feels like you are in a completely different world. With AR, you view the real world through a camera, and the technology creates an electronic image that appears to be there in real life.

For example, with Amazon’s Augmented Reality tool, you point your camera at where you want the piece of furniture you picked out to be and then click. On your screen, you will then see the furniture seamlessly appear as a part of your home, even though it’s not actually there.

So what does AR have to do with manufacturing? Augmented Reality can be useful with a lot of things, so I have listed below the top 6 potential uses for AR in manufacturing.

1. Benefits of VR Training

Today, most manufacturing companies utilize outdated training tools – papers, computerized lessons, etc. In this new age, though, we should be implementing VR training software into training employees for work on the shop floor. Imagine – instead of a booklet explaining proper procedures, the employees will be able to see a training simulation of the work they will be doing, with text/moving images to explain what the proper procedures are for whatever they are being trained in.

2. Prototyping

Prototypes can be made in lots of different ways, all depending on the product’s individual needs. They can also be very expensive, ranging from $100 to $100,000. If the manufacturing industry shifts toward Augmented Reality technology, a lot of the prototypes that would need to be made would be able to be done digitally.

The purpose of prototypes is to assess the design’s quality and risks/issues. This can be done with a computerized version in the beginning stages, instead of having to pay each time you want to change something in the prototype.

3. Assembly Assistance

In a lot of manufacturing facilities today, they use plastic sleeves filled with assembly instructions on paper. Paper is too easy to misplace or damage. To remedy this issue, there are 2 possible solutions. 1) Invest in an MES (Manufacturing Execution System) software, like CIMAG MES. Click here to learn more about what MES is all about.

Your other option is 2) invest in AR technology. Instead of using paper all over the shop floor, you can drastically reduce it by having assembly instructions being displayed through AR. Imagine being able to see what you are working on in front of you, but also seeing the next steps in the assembly process in front of you as well.

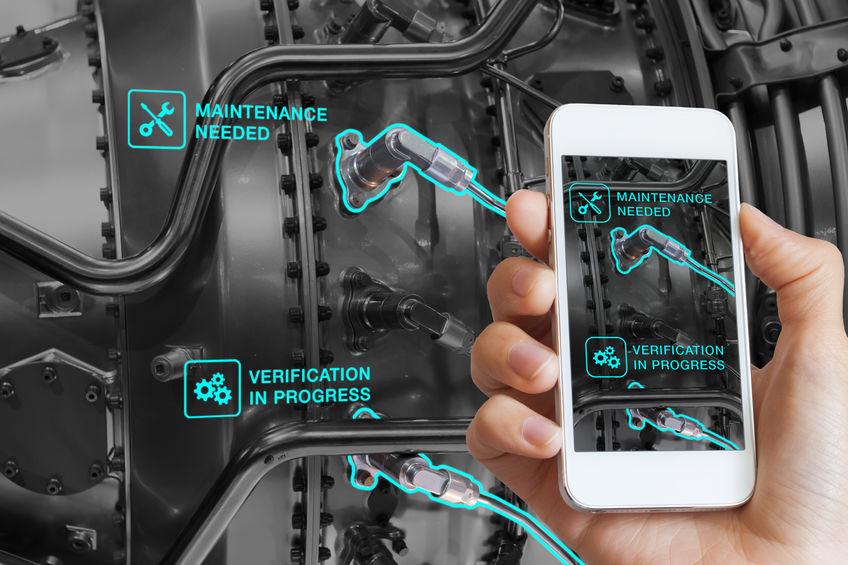

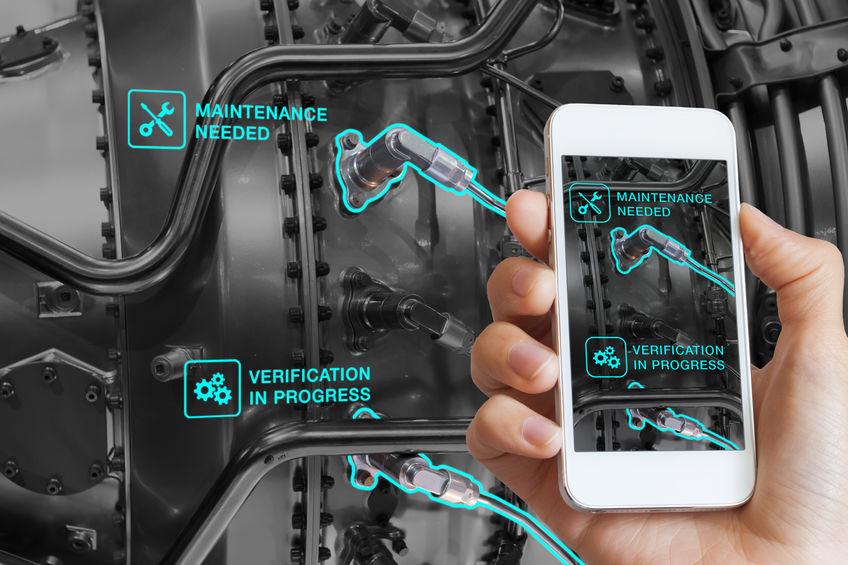

4. Error Prevention and Quality Assurance

With AR being used during assembly, it can do automatic quality checks to ensure that no errors are being made during the assembling process. Implementing this kind of technology would drastically reduce the amount of failed quality control checks as well as improve your overall OEE, due to a reduced amount of scrap.

5. Augmented Reality for Maintenance

Similar to assisting with assembly, AR can also assist with maintenance work. Maybe there is something wrong with a machine that is simple to fix, but the maintenance team is not available for a couple of hours. AR could assist the shop floor workers with remedying the situation without the help of maintenance workers.

Of course, AR is not completely ready to be implemented on the shop floor – there is still a lot of technological progress that needs to be made before that can happen. There are some places that have integrated AR into their shop floor successfully, though.

For more information on related manufacturing topics, contact us at (904) 855-8885 x105

More From Us

Keeping Your Data Safe: Blockchain Manufacturing

Keeping Your Data Safe: Blockchain Manufacturing Changing to a different network style is a big decision, but it’s a very important one to make. As...

Read MoreEnergy Management Systems – Balance Production & Energy Consumption

Energy Management Systems – Balance Production & Energy Consumption At the start of all manufacturing processes, there is energy. In fact, all products you see...

Read MoreWhat is a Manufacturing Execution System?

What is a Manufacturing Execution System? When it comes to manufacturing, both ensuring efficiency and streamlining production are crucial to profitability. How a facility goes...

Read MoreThree of the Top Manufacturing Goals

The manufacturing arena is a constantly evolving space, with new emerging technology and improved best practices being implemented at all times. Manufacturing goals are generally...

Read More